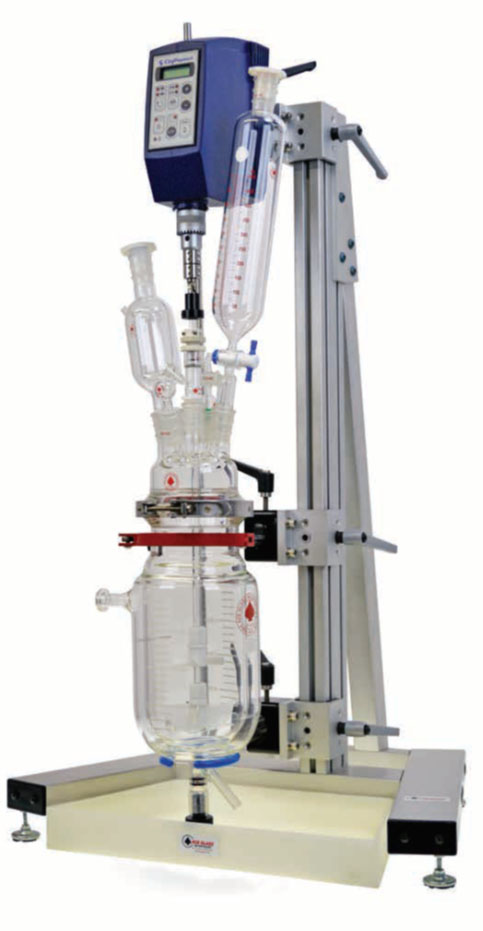

While Designing the Jacketed Glass Reactors Chemical Engineers always have challenge as the Reactors demand lot of utilities. The fumes Hoods and Isolators have to be used judicially to ensure keep as much space available and use as many equipment as possible for Laboratory scale Reactions.

In order to achieve the above Most of the Reactors should be accommodated with less height and compact design and Interchangeability.

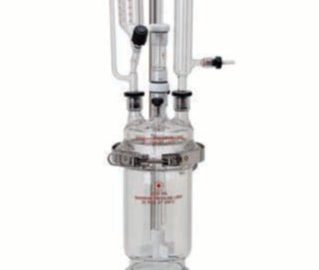

Ace Glass Reactors have a provision for Interchangeable flasks with common Head from capacities in Lab scale from 500ml, 1L ,2L AND 3L Common Head and 5L,10L & 20L common head which can be installed in Bench Hoods, Isolators under 1.2meter Height.

With the above design Chemists need not spend more money on Reactor assemblies. They have to spend only 25% of the Reactor cost to have a different batches and reaction vessels. Since the assemblies are designed with adjustable height shafts can accommodate various sizes flasks and are easy to remove and replace. Saves money and space and the capital Investment.

KILO LABS

The floor place in Kilo Labs is very expensive to build and have to be used judicially. Using compact machines can accommodate more machines and less maintenance costs.

Most of the Ace Glass Reactors have a provision for Interchangeable flasks with common Head. For Pilot Plant Reactors Ace Can provide common Head of 10L, 20L, 30L Reactors and Common head for 30L, 50L, & 100L, 150L Reactors both Jacketed and Unjacketed. This would allow the Chemical Engineers for easy scale up with less than 25% of the Reactor cost and need not spend more money.

Ace Glass Reactors are mounted on skid and uses less Floor space and can be moved to utilities. Also Ace Glass design Kilo Lab Reactors keeping Height into consideration. More the height more difficult for the maintenance. For already built up labs- NO RETROFITTING AND ADDITONAL COSTS FOR CHANGES. Move the reactor to the utilities.

MAINTAINANCE

Engineers and Production personnel often spend more time on the floor fixing the Reactor assembly as lot of utilities have to be made operational. It would be ideal to have Reactor assemblies with easy fixing and removal which can save the companies cost of man hours.

Ace Glass Reactors have pre aligned motor mounting assembly. The alignments of the assembly are easy and quick for the operators. All the Glass joints wherever applicable Ace Uses Patented Thred Technology. This allow easy connections and user friendly. Since there are not many spring joints unlike other manufacturers breakage of glass is less. Breakage means delay in production and operational costs.