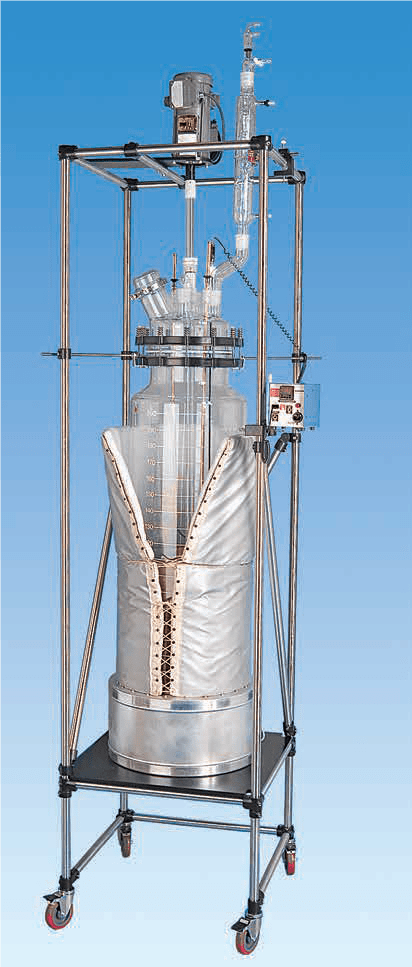

GLASS REACTORS CYLINDRICAL UN JACKETED KIL0 SCALE COOLING AND HEATING 200L

200L Reactors w/Support Stand: Black epoxy-coated aluminum flask support plate is adjustable vertically, to allow room under flask for various outlet receptacles. Plate is supplied with three adjustable braces to hold mantle in place. Upper support brackets supplied to stabilize flask.

Unjacketed Kilo Systems include:

• 4 Post Reactor Stand

• Unjacketed Flask

• Head, Coupling and O-Rings

• Agitator, Stir Shaft, Bearing & Collar

• Lid and Clamp

• Bottom Drain Valve

• Heating Mantle

• Temperature Controller with Pr

You must be logged in to post a review.

Reviews

There are no reviews yet.