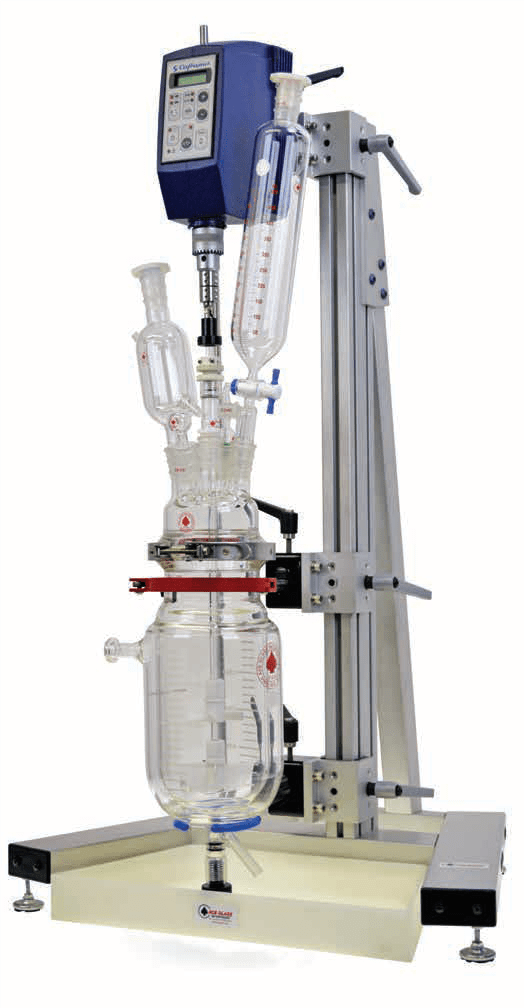

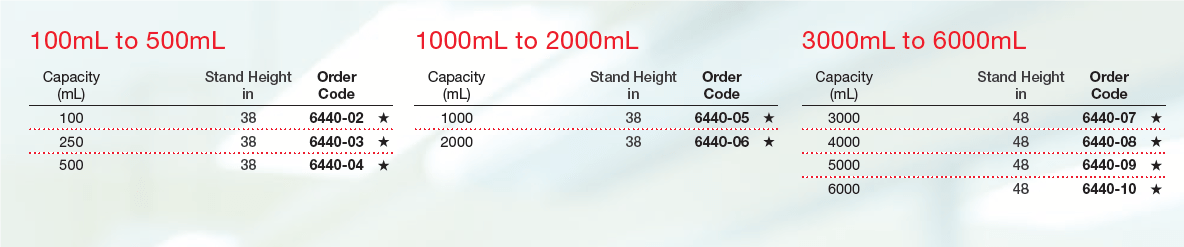

ALL GLASS JACKETED REACTORS BENCH TOP ACE GLASS 100ML, 250ML, 500ML, 1L, 2L,3L,5L AND 6L

Ace Glass Scale-Up Series™ reactor systems enable the researcher to scale-up from 100mL to 6000mL on the bench and enjoy the same geometry when replicating those results in our Kilo Scale reactors. Simply select the capacity you desire in the base system seen below. Complete your system with any of the many optional components we offer: Scale-Up Systems include:

• Single Reactor Stand

• Bolt Latch Clamp

• Support Ring

• Jacketed Flask with O-Ring and Clamp

• Flange Clamp and Gasket

Reviews

There are no reviews yet.