Sanitary pressure mixers are essential in industries that emphasize hygiene, containment, and integrity of products. The industries that need these advanced mixing systems include the pharmaceuticals, biotechnology, food processing, cosmetics, and specialty chemicals industries to ensure that there is no contamination in the production environment. In comparison to traditional open mixers, sanitary pressurizable mixers work in a closed, controlled environment, which greatly reduces the exposure risks, cross-contamination, and loss of product.

These mixers are safer, cleaner, and more efficient by providing hygienic construction with the capability of pressure or vacuum.

What Are Sanitary Pressurizable Mixers?

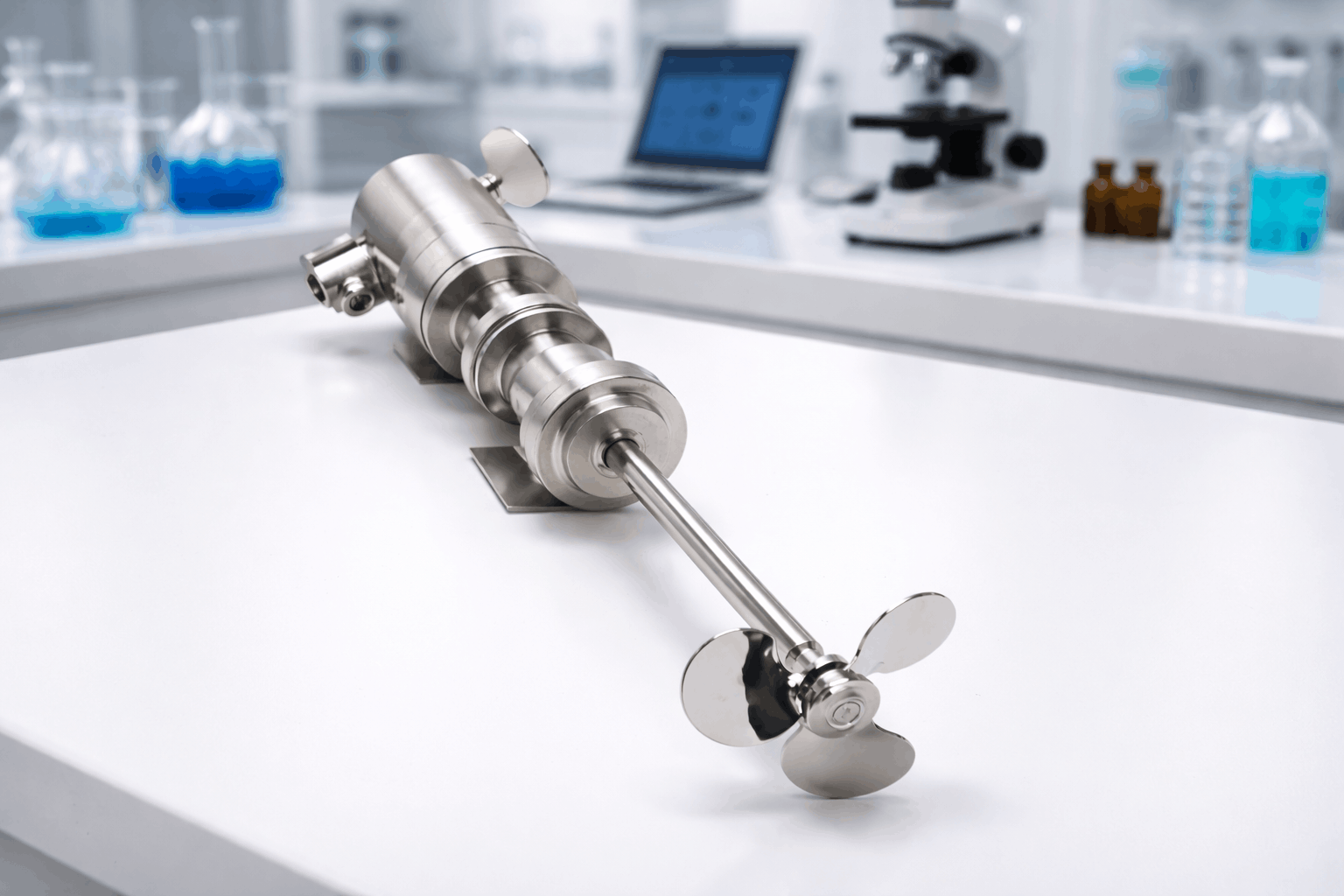

Engineers design sanitary pressurizable mixers as special-purpose mixing systems that operate under controlled pressure or vacuum in highly hygienic environments. Manufacturers construct these systems using sanitary-grade materials such as polished stainless steel to ensure compliance with Good Manufacturing Practices (GMP) and other regulatory standards.

The closed-system design also enables the operators to carry out blending, mixing, emulsifying, or processing without subjecting the materials to the external environment. This especially matters in the case of dealing with sterile, toxic, volatile, or highly sensitive substances.

How They Enhance Hygienic Processing

Sanitary pressurizable mixers are designed to enhance hygienic processing by taking into consideration the engineering and the operation. Key advantages include:

- Closed-System Operation: The sealed design prevents air contamination, human contact, and environmental exposure during processing.

- Pressure and Vacuum Control: Regulated pressure or vacuum conditions reduce oxidation, evaporation, and contamination risks.

- Hygienic Construction Materials: High-grade stainless steel with smooth, polished internal surfaces prevents material buildup and supports easy cleaning.

- Clean-in-Place (CIP) Compatibility: Some systems are designed to be fully compatible with CIP cleaning, allowing equipment to be cleaned by bypassing a mechanical sanitation process and thereby saving time and effort.

- Less Product Handling: The mixing takes place in one closed vessel, reducing material transfers that may lead to contamination of hygiene.

As a combination, these aspects guarantee consistent and safe as well as compliant production.

Key Design Features Supporting Hygiene

Sanitary pressurizable mixers are designed with special characteristics that are not available in conventional mixing systems:

- Smooth and crevice-free internal surfaces.

- Hygienic seals and gaskets

- Pressure-rated vessels

- Managed outlet and inlet ports.

- Inspection, validation, and certification are easily accessible.

These aspects make cleaning, validation, and regulatory documentation easier, which is a major requirement in controlled manufacturing settings.

Benefits for Regulated Industries

The sanitary hygienic design of sanitary pressurizable mixers brings tangible payoffs in regulated industries:

- Improved Safety on the Product: The risk of contamination is lowered, which guarantees the product increased reliability.

- Regulatory Compliance: Hygienic and sealed designs: Hygienic and sealed designs facilitate GMP and other regulatory requirements.

- Enhanced Process Consistency: The controlled environments are characterized by uniform mixing and reproducibility.

- Fewer Operational Risks: The less contact between operators and dangerous or sensitive material will increase workplace safety.

- Reduced Downtimes: Cleaning systems are minimized, and the handling of manual work is minimized.

Why Pressurizable Designs Matter

Pressurizable systems are crucial in being able to preserve the hygienic integrity in the process. These designs:

- Avoid external environmental contamination.

- Restrict contact with air and moisture.

- Provide reactive/volatile material safe handling.

- Ensurethe quality of products during the process.

Pressurizable mixers offer better control, safety, and reliability when compared to open or non-pressurized mixers.

Choosing the Right Equipment Partner

Choosing the equipment is just one of the components. Collaboration with the manufacturer with a good reputation will guarantee reliable equipment, documentation, compliance with regulations, and long-term technical support.

This is where the difference exists with Srilekha Bio Envirotech.

Learn About Hygienic Mixing Solutions

The Srilekha Bio Envirotech produces an advanced sanitary pressurizable mixer to satisfy the strenuous needs of controlled processing industries. Their systems have elaborate technical specifications, process-based design, and comprehensive documentation, and allow manufacturers to make informed decisions.

Take the next step toward improved hygiene and process control by discovering the sanitary pressurizable mixers and engineered solutions from Srilekha Bio Envirotech.