An inert atmospheric system replaces reactive gases like oxygen with non-reactive gases such as nitrogen or argon. It maintains the desired quality of the product, minimizes the risk of fire and explosion, and avoids unnecessary chemical reactions due to the presence of a controlled environment.

The Need for Controlled Environments

Most industrial products are oxygen and moisture-sensitive. Some of these chemicals may also oxidize rapidly, and fine powders may become combustible on exposure to air. Even small levels of contamination can cause batch failures, regulatory problems, or even safety risks.

A stable protective environment is used in industries to keep a constant and secure atmospheric system in the presence of:

- Combining and amalgamation processes.

- Chemical reactions

- Powder handling and storage

- Pharmaceutical processing

- Sensitive product packaging.

In managing the surrounding atmosphere, the manufacturers have better control over the whole production process.

Key Reasons Industries Use Inert Atmospheric Systems

1. Fire and Explosion Prevention

Flammable vapors and combustible dust can ignite in the presence of oxygen. Inert systems reduce oxygen concentration, minimizing the risk of ignition. This is particularly critical in chemical plants and solvent-based processing.

2. Oxidation Control

A significant number of substances are destroyed through exposure to oxygen. Oxidation may alter chemical composition, decrease strength, or alter product appearance and texture. The materials are shielded against such reactions by an inert atmosphere.

3. Product Quality and Consistency

A controlled environment also means that all batches are of the same standard. This enhances reproducibility, and variability of production is lessened.

4. Regulatory Compliance

The industries that are regulated by GMP and other regulatory bodies are required to show high levels of environmental control. Non-interventional systems of the atmosphere help to adhere to compliance by ensuring documented safety and process standards.

5. Extended Shelf Life

Exposure to oxygen can cause shortening of the shelf life of products in the food and pharmaceutical industries. There are inert systems that maintain the freshness and stability.

Industries That Benefit the Most

Several sectors rely heavily on inert atmospheric systems:

- Pharmaceutical manufacturing

- Chemical processing

- Food and beverage packaging

- High-end chemical manufacturing.

- Making of batteries and electronics.

- Powder handling industries

All these industries have distinct risks that are reduced by a controlled environment in the atmosphere.

Additional Operational Advantages

In addition to safety and quality, inert atmospheric systems have a set of operational advantages:

- Reduced material waste

- Improved worker safety

- Lower contamination risks

- Increased effectiveness of processes.

- Improved environmental management.

These systems are not merely protective; they serve as reliable long-term investments that industries can depend on.

Conclusion

Industries use inert atmospheric systems to create safer, less toxic, and more controlled production environments. Manufacturers can minimize risks, preserve the product quality, and safeguard it with inert gases replacing reactive air, and ensure compliance with the protective regulations. Inert systems are no longer a choice in high-risk or high-precision industries, and they are necessary.

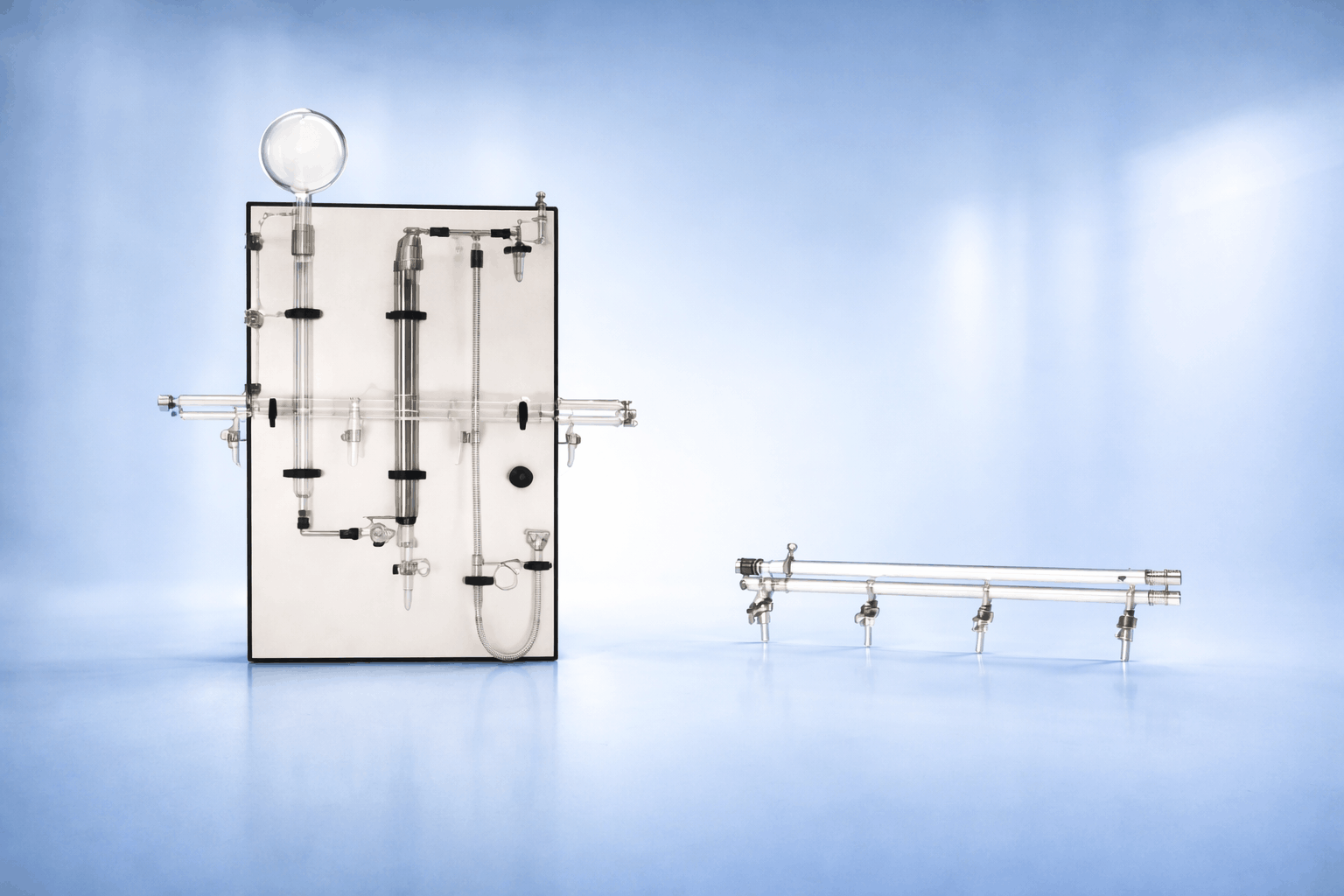

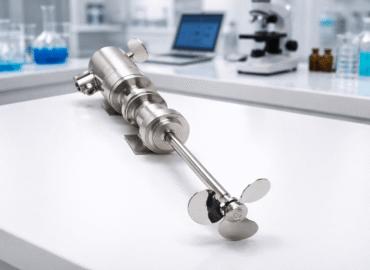

Upgrade Your Process with Advanced Inert Atmospheric Solutions

In case your facility needs more safety, contamination control, or oxygen-sensitive processing, consider advanced inert atmospheric system solutions from Srilekha Bio Envirotech.

Srilekha Bio Envirotech offers dependable systems that assist in ensuring safety, compliance, and excellence in operations through engineered designs to suit the controlled industries.

Make the next step to safer and more efficient production.