With the current developments in chemical research and industrial processing, there is an increase in demand for reliable, safe, and efficient reactor systems. Asahi glass reactor equipment ranks among the most reliable solutions in the global market because it offers precision engineering, strong chemical resistance, and high performance. Laboratories, pilot plants, and full-scale industrial facilities across multiple industries actively use these reactors for their operations.

Why Asahi Glass Reactors Are Industry-Leading

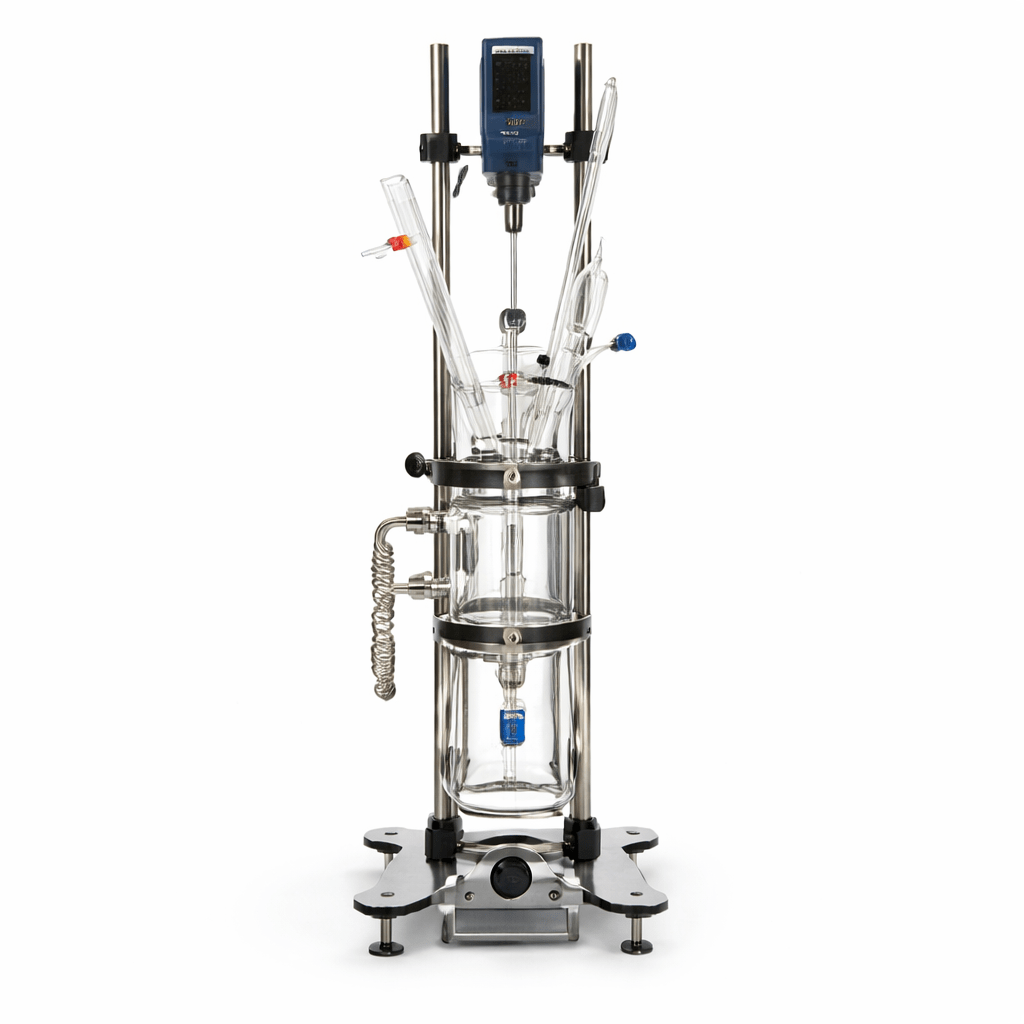

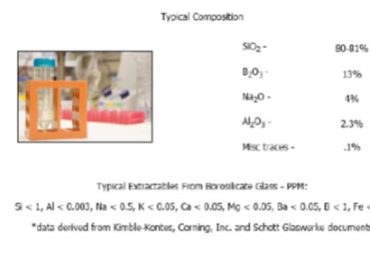

Asahi glass reactors are manufactured using high-quality borosilicate glass, designed to withstand extreme temperatures, pressure variations, and aggressive chemical reactions. Their transparent construction allows operators to visually monitor reactions in real time, improving safety and accuracy.

Key advantages include:

- Superior acid, alkali, and solvency resistance.

- Extremely high thermal stability of heating and cooling processes.

- Open design to have a clear visibility of the reaction.

- Low maintenance and long life of operation.

These features render them suitable to research driven labs as well as harsh industrial settings.

Applications Across Laboratories and Industries

The Asahi glass reactor apparatus has found numerous applications in various areas because of its flexibility and expandability.

Common application areas include:

- Drug formulation and pharmaceutical research.

- Synthesis and process development, chemical.

- Fermentation procedures and biotechnology.

- Production of specialty and fine chemicals.

- Scholarly and research laboratories.

These reactors are both consistent and reproducible, whether in the small-scale experiments or pilot-level production.

Key Features of Asahi Glass Reactor Equipment

The contemporary Asahi glass reactors are constructed with the modern features that can aid accurate process control and operational safety.

Notable features include:

- Standardized planning is to be easily customized.

- Effective mixing mechanisms.

- Jacketed vessels to ensure good temperature control.

- Seals and waterproof joints of high quality.

- Vacuum and pressure compatibilities.

These characteristics enable the operators to optimize responses and yet ensure high safety levels.

Benefits for Industrial Operations

To industries, the cost of high quality glass reactor system has a direct proportional relationship to improved productivity and minimized risks of operation.

Industrial benefits include:

- Enhanced efficiency and consistency of processes and reactions.

- Less pollution and contamination.

- Validation and easy cleaning.

- Adherence to international protocols of laboratory and manufacturing.

This predisposes Asahi glass reactors to be an economical and reliable option in long-term operation.

Choosing the Right Supplier Matters

Even the finest equipment will do best only when supplied by a reliable supplier who knows what is needed to do and gives appropriate support. Quality suppliers guarantee proper installation, customization, and after-sales services, which are important to continuous workflows.

Upgrade Your Reactor Systems with Srilekha Bio Envirotech

Srilekha Bio Envirotech is the reliable provider of the highest quality Asahi glass reactor equipment in the laboratory or industry. Srilekha Bio Envirotech focuses on quality, performance, and customer satisfaction; therefore, it delivers reliable reactor solutions tailored to your process needs.

Moreover, these advanced glass reactor systems improve accuracy, safety, and productivity. As a result, contact Srilekha Bio Envirotech today and confidently take your laboratory or industrial operations to the next level.