Currently, there has been an escalating interest from laboratories engaged in pharmaceuticals, fine chemicals, and material studies in state-of-the-art methods for separation. Some of the hottest searches today involve short path distillation systems, as laboratories are increasingly looking for a safe way to handle temperature-sensitive materials, thus adopting a preferred solution such as short path distillation.

Instead of the usual, customary giant distillation systems, scientists are focusing on more controlled options.

Understanding the Demand for Low-Temperature Separation

Among the top reasons why short path distillation systems are trending is their ability to work under significantly lower temperatures. This is particularly vital if one is working with compounds that tend to degrade in the presence of heat.

Key advantages researchers are seeking include:

- Reduced thermal stress of the materials

- Preservation of compound purity

- Quicker processing times

These benefits are also in close alignment with current pharmaceutical and speciality chemical development research goals.

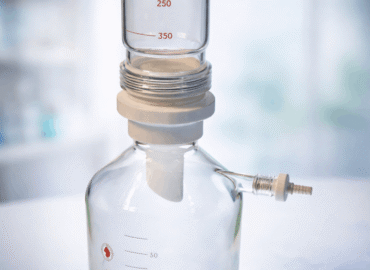

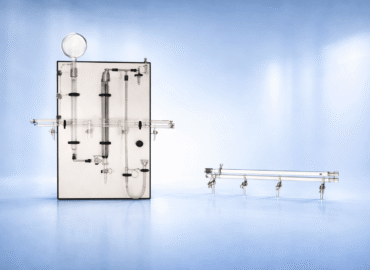

Compact Design Advantages of Short Path Distillation Systems

The other contributing factor could be related to space efficiency. Indeed, modern laboratories operate within constrained environments, embodiments of which are required.

Trending topics emphasize the following:

- Smaller distillation systems make workflow organization easier because of their

- Compact systems simplify installation work

- The modular design facilitates an upgrade

Thus, short path distillation apparatuses are generally more preferable in pilot lab settings where flexibility is a highly desirable commodity.

Improved Efficiency and Yield Control

Yield optimization is one of the biggest issues in the chemical research sector. Conventional distillation may lead to material losses because of prolonged residence time and inadequate condensation.

Currently, scientists prefer models with:

- Short residence time of chemicals

- Accurate control of the vacuum

- Effective vapour condensation

All these elements lead to increased rates of recovery; hence, short path distillation systems are often highlighted in scientific forums.

Safety and Process Transparency as Key Trends

Safety has emerged as another focus in lab equipment. The condition that ensures reduced exposure of the operator and enhances observation has become more sought after.

The trending safety-related benefits include:

- Sealed distillation paths

- Minimized risk of decomposition and pressure failure

- Improved visibility of the process

Owing to the above advantages, short-path distillation equipment is commonly chosen in lab setups where the requirements of safety and legal compliance are not negotiable.

Why Short Path Distillation Technology Continues to Trend

This increasing use of precision laboratory procedures also implies an increasing demand for advanced separation methods. With laboratories emphasizing reproducibility, efficiency, and compound integrity, demand for short-path distillation systems will also continue to be strong.

Conclusion

The modern lab is revolutionizing the aspect of separation methods by adopting technology that focuses on efficiency, safety, and conservation of materials. The short path distillation technique is also being transformed by responding to various challenges that exist in the process of distillation. The knowledge about the trend of this technique is fundamental for researchers to make correct choices while maintaining a lab setup.

Laboratories looking to implement or upgrade short-path distillation systems can explore available laboratory and pilot-scale systems offered by Srilekha Bio Envirotech. Detailed product specifications, configurations, and application-related information are available at Srilekha Bio Envirotech, enabling researchers and technical teams to evaluate suitable equipment for temperature-sensitive separation processes.