With the ever-increasing complexity of research in the field of chemistry and the pharmaceutical sector, there is an increasing need for reactions that take place in high-pressure environments. As a result, the need for pressure-rated equipment is becoming a topic of interest in research planning. Pressure reactors are no longer a prerequisite in research facilities but have become a necessary component in a research lab.

This is based on changes in reaction chemistry, safety requirements, and process optimization.

The Growing Need for Controlled Reaction Conditions

In a large number of current chemical reactions, it is impossible to work at or near atmospheric pressure. In hydrogenation reactions, polymerization reactions, or catalytic reactions, a controlled setting of pressures is necessary.

Pressure reactors allow labs to:

- Preserve constant pressure during a reaction

- Enhance reaction rates & yields

- Handle gases and volatile substances carefully.

Consequently, due to its capabilities, pressure-rated equipment is being perceived as a must-have rather than a complementary addition.

Supporting High-Performance and Specialized Reactions

Another reason pressurized systems have gained popularity is their suitability to support reactions, which in open reactors could be challenging. Reactions carried out at higher pressure have been observed to be affected by the pressure.

Some of the trending research applications are:

- Catalytic synthesis

- Gas-liquid reactions

- Material and Polymer Development

As scientific studies become more focused, the use of pressurized reactors increases the range of experimentation that the lab can perform.

Safety and Compliance Driving Equipment Adoption

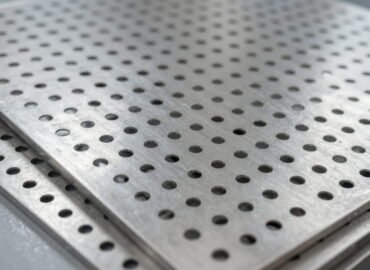

The standards of a laboratory have become more rigid, especially in the context of pressurized systems and dangerous chemicals. The use of pressurized reactors manufactured using reinforced materials and sealed components reduces the hazards of leaks and exposure.

Safety-related key factors include:

- Decrease in operator exposure to reactive materials

- Enhanced containment of pressurized reactions

- A smoother alignment with legal requirements

All these factors are making pressurized systems a common point in discussions related to laboratory safety.

Transparency and Monitoring in Modern Reactor Design

Modern pressurized systems aren’t “black boxes” anymore. Researchers increasingly expect equipment to monitor and collect data throughout the reaction process.

Current trends put much emphasis on:

- Integration with the sensors of temperature and pressure

- Increased visibility through all-glass or glass-lined designs

- Compatibility with data recording systems

This level of transparency enables reproducibility and optimization of processes, which are particularly important in contemporary research conditions.

Preparing Laboratories for Scale-Up

Pressurized systems are also used in addressing scale-up differences between lab experiments and pilot-scale manufacturing. Laboratory equipment that works well on a small scale facilitates predictions on how the reactions will work on a larger scale.

The ability to easily scale up makes the pressurized systems very useful for lab applications related to process development and applied research.

Conclusion

The rising adoption of pressure reactors is indicative of the evolving nature of scientific research and development in the lab towards adopting more controlled and safe methods of scientific research and development. With research heading into high-performance reactions and complex chemical systems, it is clear that pressure-rated equipment will be an integral part of lab development in the future.

Laboratories interested in pressure-rated reaction equipment may find the currently available lab and pilot reactors supplied by Srilekha Bio Envirotech to be worth reviewing for possible usage. For more information on specifics and for application-related details, please visit Srilekha Bio Envirotech.