Separations and mass transfer operations have been important in the chemical and process industries for achieving high-quality products and efficient processes. Columns with perforated plates are among the most widely used internal column designs for gas–liquid and liquid–liquid contact. Companies use them widely because manufacturers design them to be simple, dependable, and economical.

What Are Perforated Plate Columns?

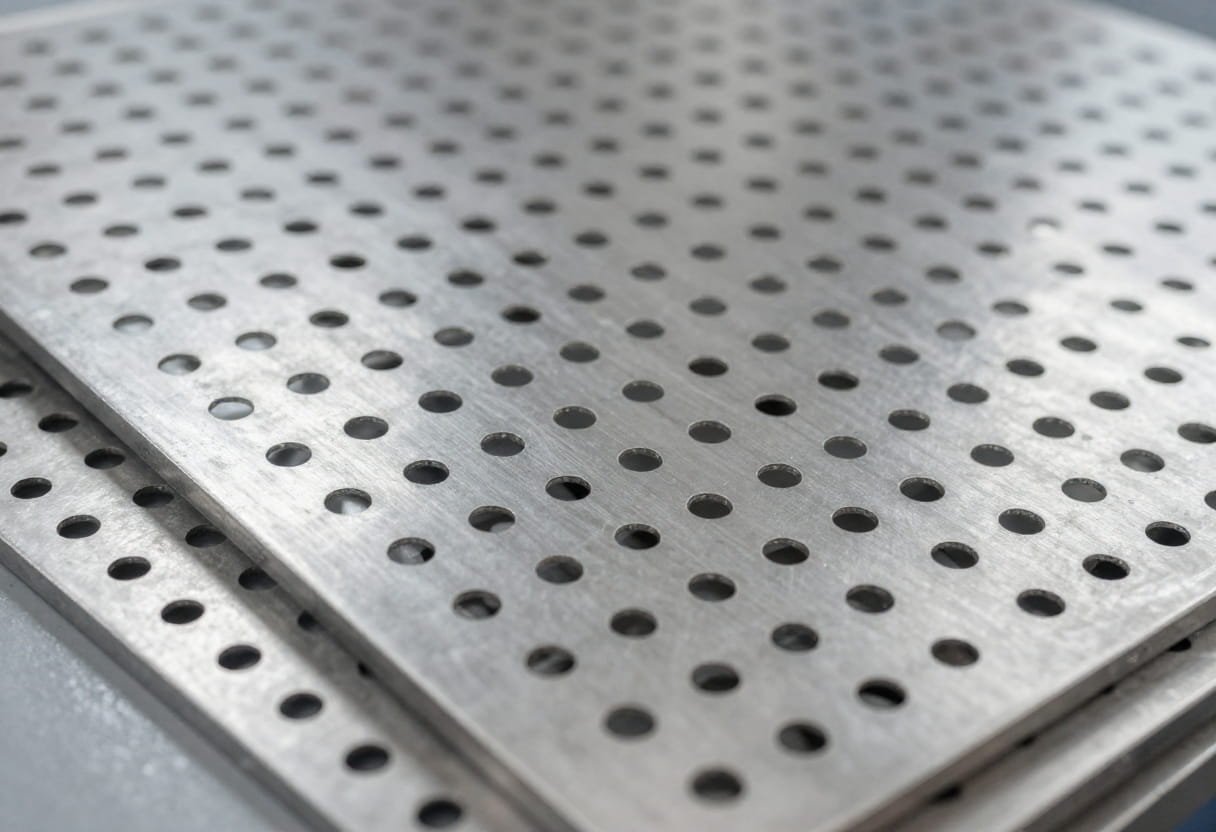

Perforated plate columns consist of vertical passages equipped with horizontal trays, which are well-drilled. These holes enable vapour or gas to ascend through the liquid that flows over each tray and bring the phases into close contact. This regulated interaction improves the efficiency in mass transfer and stability in the functioning of varying process conditions.

Compared to packed columns, columns with perforated plates offer easier maintenance, better handling of fouling systems, and predictable performance over a wide operating range.

Working Principle

A perforated plate column works by stage contact:

- Downcomers are used to direct the flow of liquid down the tray to tray.

- Vapour or gas ascends through perforations in every plate.

- Turbulent mixing occurs on each tray, making the mass transfer process effective.

- Engineers consider the plates as theoretical equilibrium stages.

This design controls the stages more effectively, improving separation efficiency and process stability.

Key Advantages of Perforated Plate Design

Several attributes motivate industries to use this type of column.

- Basic mechanical construction and reduced construction cost of fabrication.

- High performance in moderate to high vapour and liquid flow rates.

- Operators can inspect and clean it more easily than packed internals.

- Fouling or dirty service ability.

- Elasticity in the response to process load changes.

These advantages make columns with perforated plates suitable for long-term industrial operations.

Applications Across Industries

Many industries widely apply perforated plate columns.

- Chemical and petrochemical processing.

- Distillation and fractionation units.

- Absorption and stripping systems.

- Solvent recovery processes

- Environmental and effluent treatment plants.

In environmental engineering, these columns support gas absorption and treatment, where reliable operation is essential.

Design Considerations for Optimal Performance

Engineers must carefully design several parameters to ensure successful operation.

- Diameter and spacing of plate holes.

- Diameter of column and tray spacing.

- Liquid and vapour load capacity.

- Corrosion resistance material selection.

- Sound downcomer design to prevent flooding.

A well-designed column with a perforated plate system ensures high efficiency, reduced pressure drop, and consistent output quality.

Why Choose Srilekha Bio Envirotech?

Selecting the appropriate manufacturing and engineering partner ensures reliable performance. Srilekha Bio Envirotech specializes in designing and fabricating customized columns with perforated plates tailored to specific process requirements. The company provides solutions which sustain efficient and sustainable operations, with a very high level of attention to the quality, durability, and environmental compliance.

Contact Srilekha Bio Envirotech today and talk about your project requirements and find the best professionally designed column solutions to increase your performance and reliability of the processes.