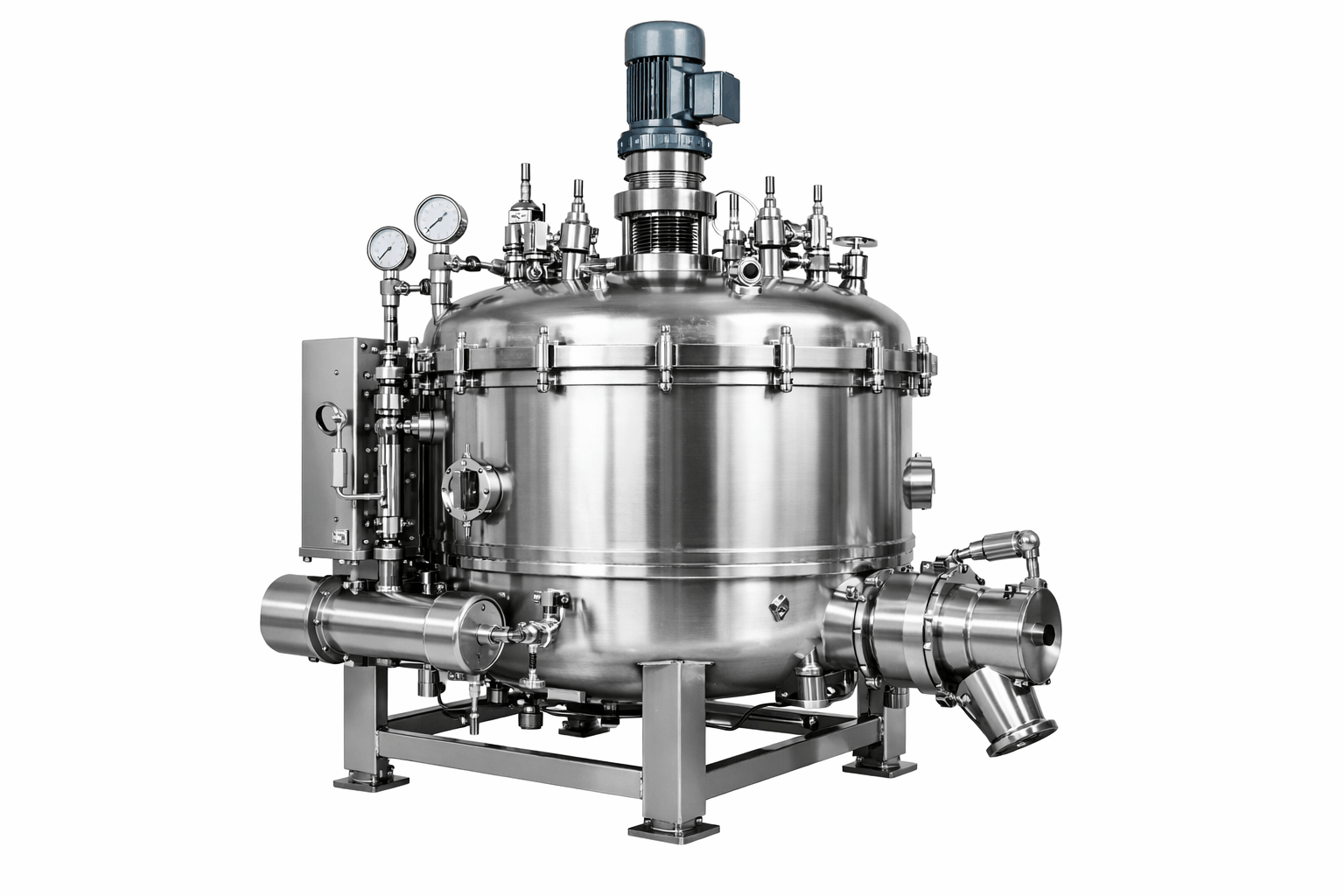

Nutsche Filter Dryers play a crucial role in modern chemical, pharmaceutical, and food-processing industries. Manufacturers design these units to achieve solid–liquid separation and drying within a single closed system, enhancing efficiency, safety, and product purity. This equipment has become an industry standard as the industries are working more on contamination-free and automated processing.

What Are Nutsche Filter Dryers?

A Nutsche Filter Dryer performs filtration, washing, and drying of solids in a single vessel. Operators can run it under vacuum or pressure, making it especially useful for handling hazardous, toxic, or high-value substances.

The contamination and loss of materials are highly reduced because all of the operations are performed within a closed space. This makes the system appropriate in the industries where the regulatory requirements are strict.

Key Industrial Applications

Nutsche Filter Dryers are commonly used in many different industries thanks to their wide applicability.

Common applications include:

- APIs and pharmaceutical intermediates.

- Fine chemicals and specialty chemicals.

- Bio-pesticides and farm chemicals.

- Food products and nutraceuticals.

- Dyes and pigments.

They maintain product integrity during processing, which makes them essential for sensitive operations.

Advantages of Using This Equipment

The reason why modern manufacturers like using this equipment is that it involves a combination of several processes within a small system.

Key advantages include:

- Filtration, washing, and drying of single units.

- Less manual operation and human contact.

- Better purity and uniformity of the product.

- Reduction in operating and maintenance costs.

- Adherence to standards of GMP and safety.

Production time is minimized,d and the quality is not compromised with fewer transfer steps.

Why Closed-System Processing Matters

Safety and efficiency in the present manufacturing world are two inseparable ideas. Nutsche Filter Dryers offer closed-system processing, which minimizes operator contact with hazardous substances. Operators must strictly follow this practice when handling toxic solvents, volatile substances, or sterile products.

Closed systems enable efficient solvent recovery and support environmental protection, aligning with sustainable manufacturing practices.

Choosing the Right Equipment Partner

The selection of the supplier is similar to that of selecting the equipment. The system that suits your process requirement will be effective and reliable in the long run, scalable, and regulatory-compliant.

When considering suppliers, consider:

- Customization capabilities

- Quality and design requirements of materials.

- Maintenance and after-sales support.

- Experience and certifications in the industry.

Final Thoughts

In an ever-changing environment of more secure and efficient technology-based industries, the use of this integrated filtration and drying system for the blending of solids and liquids ensures uninterrupted service. They can provide consistent output at a lower risk, and this makes them an excellent investmentfore contemporary plants.

Process Smarter at Srilekha Bio Envirotech

We are Srilekha Bio Envirotech, which specializes in high-quality process equipment engineered to perform well, stay safe, and comply. Our advanced filtration and drying solutions are designed to meet the demanding needs of today’s industries.

Reach out to Srilekha Bio Envirotech now to modernize your processing capacity using effective solutions.