Precision, safety and efficiency are irreplaceable in modern laboratories as well as in pilot plants. In pharmaceuticals, chemicals, biotechnology, or research institutions, the separation and the purification processes should provide consistent results within the strict regulatory conditions. This is where custom lab distillation systems become very important. This is unlike standard, off-the-shelf equipment because custom-built distillation systems are designed to suit the old operational requirements of a particular process, thus offering high throughput and reliability.

What Are Custom Lab Distillation Systems?

Custom lab distillation systems are custom-designed systems designed and built depending on the parameters of the processes of a laboratory. Such parameters usually comprise operating temperature, pressure conditions, solvent characteristics, throughput capacity and desired purity levels. These systems should be designed by engineers to fit in the current laboratory infrastructure and meet all the safety and regulatory requirements.

Due to the fact that each lab process is different, customization enables researchers and operators to attain greater efficiency, better control, and increased reproducibility than generic systems.

Why Customization Matters in Laboratory Distillation

Simple applications can be achieved with standard distillation units; however, when dealing with complex or sensitive processes, custom-made solutions are required. Custom systems enable the laboratories to optimize all parts of the system, such as column design, condenser choice, and so on, taking into consideration the actual requirements in the process.

The most notable benefits of the custom lab distillation systems are:

- Design that enhances separation efficiency, which is process specific.

- Improved safety level according to solvent and pressure demands.

- Increased purity production by maximizing structure.

- Scalability between the laboratory scale and pilot scale.

- Less downtime of operations with enhanced system compatibility.

Custom systems enable the laboratories to obtain repeatable and consistent results by concentrating on the specific needs of any given process.

Applications Across Industries

Practically any industry is not enough to be without custom lab distillation systems, which include but are not limited to:

- Pharmaceuticals: API purification, intermediate processing, and solvent recovery.

- Chemical industry: Specialty chemical separation, fractional distillation.

- Biotechnology: Delicate partitioning of temperature-sensitive compounds.

- Research and development: Distillation research and pilot-scale research.

The systems used in each of these industries provide control and flexibility with precision and do not conflict with the industry regulations.

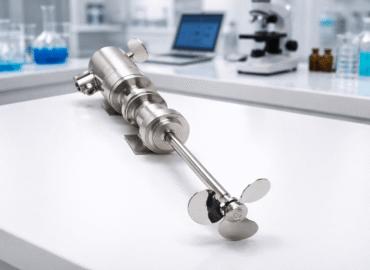

Key Features of High-Quality Custom Distillation Systems

Designing a custom distillation lab system, vendors concentrate on the performance, safety and convenience. Common features include:

- Brosilicate glass or stainless steel which are resistant to corrosion.

- Skilled temperature and pressure control system.

- Heating and condensation systems that use less energy.

- Easy upgrades and maintenance designs.

- Adherence to the national and international safety standards.

Such characteristics provide the system with a high level of efficiency and also facilitate long-term ability to operate.

Choosing the Right Partner for Custom Solutions

A great deal of the success of a custom lab distillation system rests on the experience of the manufacturer. A competent partner has knowledge of process chemistry, engineering design and regulatory compliance. They collaborate with the clients to understand their needs, develop the best solutions, and offer after-sales services.

Conclusion

If you need high-quality, efficient, and fully customized lab distillation systems that deliver accuracy and performance, collaborate with Srilekha Bio Envirotech. The company focuses on quality engineering and customer-specific solutions to design and manufacture distillation systems for laboratories and pilot plants.

Call Srilekha Bio Envirotech today to discuss your requirements and take the first step toward safe, efficient, and high-performance distillation solutions.