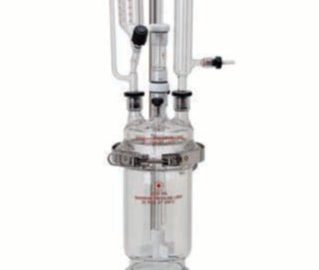

An All-Glass Filter Reactor is becoming essential in today’s rapidly accelerating laboratory and industrial environments, where efficiency is a key element of success. Whether for research, process development, or production of high-end speciality chemicals, the efficiency of your operation can make a big difference. Filtration—particularly the transfer of materials from one vessel to another—is often a time-consuming step in many workflows. This step not only reduces productivity but also exposes the process to hazards such as contamination or loss of product.

This need has encouraged researchers to adopt combined reaction/filtration systems. One such versatile instrument is the All-Glass Filter Reactor, a multi-purpose device that ensures efficient chemistry with the safety and clarity required for controlled laboratory-scale reactions.

Why an All-Glass Filter Reactor Integrated System Matters

Conventional filtration processes can necessitate transferring the reaction mixture from one vessel to another. Every transfer adds handling time and another opportunity for error. A Filter Reactor, the All-Glass combines both operations into the very same apparatus, offering a cleaner and more efficient approach.

Key advantages include:

- No transfer of material is required, which prevents unnecessary steps.

- Product loss is minimized during filtration.

- Reduced risk of contamination from contained processing.

- You can see through the glass body clearly.

- Greater safety, as the material is enclosed at all times.

- Convenient control and observation, suitable for the reaction of imbalance sensitivity.

The All-Glass Filter Reactor reduces product handling risks and improves filtration times compared to traditional funnel systems.

Built for Modern Laboratory Needs

The AG! Filter Reactor is a very general-purpose device and can be used for different applications in laboratory and pilot plant production. Offered in several size ranges, from small R&D units to large pilot plant systems can handle all of these operations and more (reacting, crystallizing, filtering, and washing) in a single vessel

Ideal for applications like:

- Pharmaceutical research and development

- Chemical synthesis and purification

- Crystallization of fine chemicals

- Solid–liquid separation processes

- Pilot plant and academic research

- Specialty material production

Its modularity, removable parts, and sturdy build make it user-friendly, so you can get up and running within days without hiring any outside help.

Safety Advantages of an All-Glass Filter Reactor

And in all chemical work, safety is first. The All-Glass Filter Reactor offers a sealed system that has been designed in such a way as to prevent exposure to respondents.

Safety benefits include:

- With a closed system to prevent spills and contamination

- Operators Less Exposed To Dangerous Materials

- Vacuum filtration system for faster, more controlled results

- Clear material for visibility during reaction and filtration

- Airtight, rugged construction for daily use and rigorous demands

This feature makes it a good option for laboratories that process sensitive or dangerous chemicals.

A Smarter Future for Filtration

Enhance your lab and plant design with this innovative, versatile Filtration Reactor. The overall output, risk, and quality of the final product are improved when sections of this process are combined into a single continuous operation.

If you want to streamline your process, save on space, and increase safety while improving your yields; The All-Glass Filter Reactor’s design is just for you.

Ready to Upgrade Your Workflow?

Discover high-performance All-Glass Filter Reactor systems designed for efficiency and precision at Srilekha Bio Envirotech.

👉 Visit: srilekhabioenvirotech.com

To explore a complete range of advanced filtration and reaction solutions.