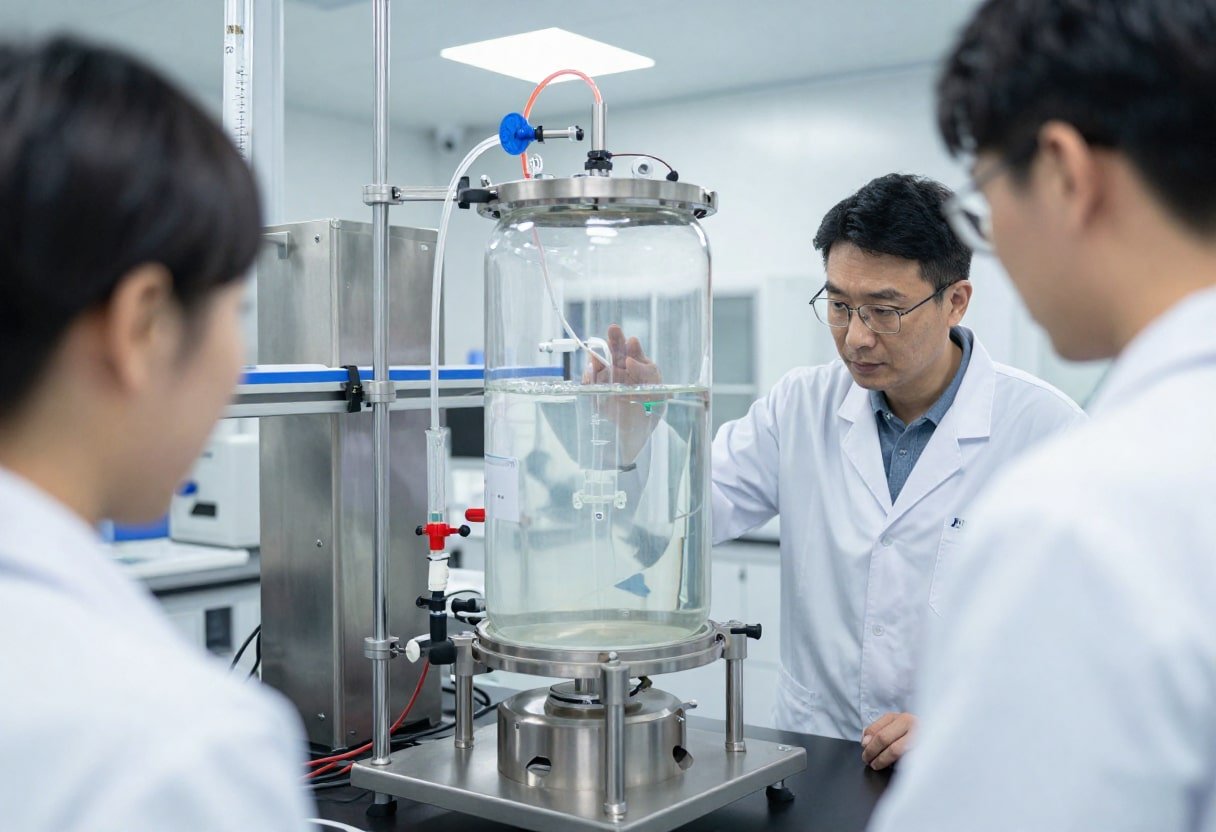

In recent years, laboratories in the pharmaceutical, chemical, and research sectors have gradually shifted from conventional reaction vessels to a more flexible and transparent laboratory solution. Recent laboratory infrastructure, among the most searched queries in the field of laboratory equipment, includes the use of glass reactor systems and the role of these systems in promoting safe laboratory practices.

“It’s not an issue of branding or marketing. It’s an issue that’s being shaped by the way scientific inquiry is being conducted.”

The Shift Toward Visibility and Process Control

One of the key reasons why labs are opting for glass-based reaction equipment is the use of visual monitoring. Compared to metal-based reaction equipment, glass equipment enables scientists to monitor the process, which assists in:

- Early Detection of Unexpected Reactions

- Monitoring of phase changes

- Enhancement of the accuracy of experiments

It is a factor that has made glass reactor systems popular in research laboratories, where precision is a major concern.

Compatibility With Modern Research Needs

Another concern related to trending is that of chemical compatibility. Many reactions involve corrosive or sensitive compounds, which require the use of inert materials or those that are non-reactive.

Glass reactors address this need by offering:

- High resistance to acids and solvents

- Reduced risk of contamination

- Stable performance under controlled temperatures

As a result, glass reactor systems are among the frequently discussed topics in forums and technical journals related to laboratory optimization.

Supporting Scalable Research Workflows

Laboratories today focus on bridging the divide that exists between experiments and production. Scientists seek a device that can handle both experimental work and production without having to restart from scratch.

Trending conversations include the following:

- Modular reactor designs are time savers

- Scalable equipment cuts expenses

- One area that is positively affected by consistency

Hence, it is clear that glass reactor systems are commonly selected for pilot plant studies and process developments.

Safety and Compliance Driving Equipment Choices

Laboratory safety in general has become more seriously addressed globally; this makes the topic of safety one of the highest priorities for lab managers and researchers of today. Glass reactors designed to bear proper pressure ratings and sealed systems will help in minimizing exposure risks.

Common safety-related benefits include, but are not limited to:

- Controlled pressure environment

- Less hazardous materials handling

- Better adherence to laboratory standards

Safety has increasingly been targeted toward the glass reactor system as the preferred option.

Why This Trend Is Likely to Continue

With research becoming increasingly cross-disciplinary and focused on efficiency, there is a focus on investment in lab equipment that is transparent, flexible, and reliable. The steady increase in demand for glass reactor systems represents a trend towards smarter, rather than quicker, solutions for the lab.

To see laboratory equipment as well as chemical process equipment according to current requirements in research, visit Srilekha Bio Envirotech for detailed product information, technical specifications, and expert support.