The equipment used in the process of distillation is very important in industries where separation and purification of liquids are critical. In chemical production, pharmaceuticals, oil and gas, food production, and environmental engineering, distillation has been one of the most acceptable and dependable methods of separation. Awareness of the operation of this equipment and its application assists businesses in selecting the appropriate system to be efficient, safe, and cost-effective.

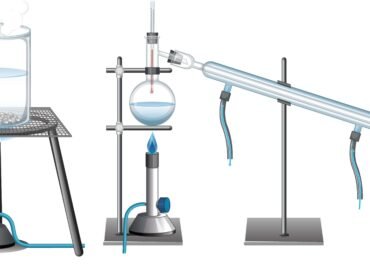

In its simplest form, distillation is a process that separates the components of a liquid mixture by using the difference in the boiling points. The distillation process heats the mixture and cools the vapour to obtain purer individual components. Distillation process equipment precisely controls heating, vapour transfer, condensation, and collection to ensure accurate separation.

Understanding Distillation Equipment

The equipment of a distillation process is defined as a combination of components that has been designed to execute the operation of the distillation process effectively. Such systems may be either basic or highly sophisticated, in regard to the magnitude and usage.

Common components include:

- Separating columns or towers by distillation.

- Reboilers to provide heat and produce vapour.

- Cool down the vapour by condensers to a liquid.

- Products separation containers and bins of separated products.

- Pumps, valves, and smooth-running control systems.

Each machine is programmed to work with particular temperatures, pressure, and chemical characteristics, and therefore provide stability in its performance and quality products.

How the distillation process equipment works

The process starts with a liquid mixture going into the distillation unit. A reboiler is used to heat the components, where the component with the lowest boiling point vaporises first. This vapor ascends through the column, whereby it can flow through trays or packing material, which enhances the separation capacity.

During its ascendancy, the vapor cools down and condenses at various levels depending on boiling points. This is then condensed as vapour and returned into the liquid that is gathered as a purified product. The industrial process is highly controlled, thus enabling the industries to obtain high levels of separation accuracy.

Industries That Rely on Distillation Systems

Distillation process equipment is essential across multiple sectors due to its reliability and versatility.

Major applications include:

- Chemical industry- solvent, acid, and specialty separation of chemicals.

- Pharmaceuticals, Pharmaceutical active ingredients, and intermediates purification.

- Oil/gas: Crude oil refining and oil separation.

- Food and drinks – alcohol distillation, flavour, and essential oils.

- Environmental engineering, wastewater treatment, and solvent recovery.

The equipment design is tailored to the needs of the regulatory requirements and the functions required by each industry.

Benefits of using modern distillation process equipment

Installing high-quality distillation systems has several benefits for the industrial processes:

- Large purity levels of products and uniform quality.

- Small to large-scale production designs.

- Air-conditioning with heat recovery and low energy consumption.

- Prolonged life with an appropriate choice of material.

- Automation and monitoring compatibility.

The use of modern equipment is also concerned with sustainability through less energy usage and the minimisation of wastage.

Key Factors When Choosing Distillation Equipment

The selection of the appropriate equipment for a distillation process must be conducted with proper consideration of the technical and operational aspects.

Key considerations include:

- Differences like the mixture and the boiling point.

- Required purity levels

- Operation temperature and pressure.

- Corrosion resistance and compatibility of materials.

- Adherence to safety and environmental regulations.

The collaboration with proven manufacturers will result in customization of the system to match your unique process requirements.

Moving toward efficient and reliable distillation solutions

With the ever-increasing efficiency required in industries, and more clean processes demanded, equipment in distillation processes keeps advancing. Modern systems have been more reliable and cost-effective than ever due to advanced designs, better materials, and automation.

In case you are planning to install or upgrade your system of distillation, you must collaborate with the correct technology provider. Srilekha Bio Enviro Tech sells competently designed distillation process equipment that is performance, safety, and long-term efficient.

Make the next move towards the effective separation and purification- get in touch with Srilekha Bio Enviro Tech and get the correct distillation system suitable for your industry.