Currently, the laboratory and pilot plant environments demand precise, safe, and chemically compatible conditions for an efficient reaction to occur. Asahi Glass Reactor is one of the widely used reactors by the pharmaceutical industry, the chemical industry, and the biotech industry because of the high standards of the materials used and the efficiency of the reactor. It is made of the highest quality borosilicate glass and can be used for handling chemicals, temperature, etc.

This paper discusses the significance, applications, and necessity of glass reactors in advanced chemical processing.

What Is an Asahi Glass Reactor?

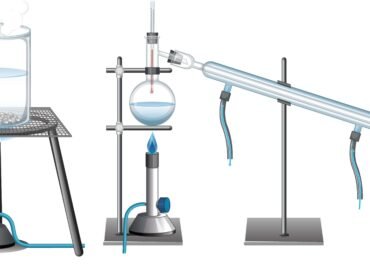

An Asahi Glass Reactor is a laboratory or pilot-scale reactor system manufactured using premium borosilicate glass that offers excellent thermal and chemical resistance. These reactors find extensive application in carrying out reactions like synthesis, distillation, reflux, crystallization, and polymerization under controlled environments.

They are designed to provide:

- High transparency to enable visibility of reactions.

- Acid resistance, alkali resistance,e and solvent resistance.

- Fine temperature and pressure regulation.

- Safe working conditions for dangerous and sensitive processes.

Key Features of Glass Reactor Systems

Multiple components work together in a properly designed glass reactor system to ensure efficiency and safety.

Common features include:

- Glass vessel of even thickness, Borosilicate.

- Heating and cooling circulatory jacketed.

- Variable speed control in the stirring mechanism.

- Reflux and solvent recovery condenser.

- Valves and temperature sensors.

Their ability to be pure and to be able to control processes makes them indispensable in the controlled industries.

Applications Across Industries

Glass reactors are considered to be versatile and reliable in various industries.

Key areas of use are:

- Pharmaceuticals: API production and technology development.

- Chemical industry: reactions of corrosive chemicals.

- Biotechnology: sterilization and temperature-sensitive.

- R and D laboratories: optimisation of reactions and feasibility studies.

- Pilot plants: before commercial manufacture.

Their capability to be pure and to be able to control processes makes them indispensable in the controlled industries.

Advantages Over Conventional Reactors

Glass reactors have a number of benefits over metal or plastic reactors.

Key benefits include:

- Very good chemical corrosion resistance.

- Easy reaction monitoring due to enhanced transparency.

- Smooth, non-reactive surface that resists contamination.

- Cleaning and maintenance are easy.

- Low degradation and long operation life.

By choosing an Asahi Glass Reactor, laboratories can achieve higher process reliability while maintaining strict quality standards.

Design and Selection Considerations

As a glass reactor is chosen, it is worth looking at:

- Working volume and batch sizeares required.

- Temperature and pressure operating range.

- Stirring type and speed required.

- Solvency Compatibility with solvents and reactants.

- Auto requirements and safety features.

An experienced supplier will work with you to configure the right system for your specific application.

Why Choose Srilekha Bio Envirotech?

Srilekha Bio Envirotech deals with the supply of glass reactor systems of high quality that are of international standards in terms of safety and performance. The company pays attention to comprehending what clients want to get and providing tailored and trusted solutions.

What sets them apart:

- Good equipment purchased from reputable suppliers.

- Process customization.

- Adherence to laboratory and industrial safety standards.

- Timely technical support/after-sales.

If you are looking for a reliable and efficient Asahi Glass Reactors for your laboratory or pilot plant, partner with Srilekha Bio Envirotech today. Contact their team of experts and talk about your application, and get a solution that helps to improve the safety level, efficiency, and accuracy of the process.